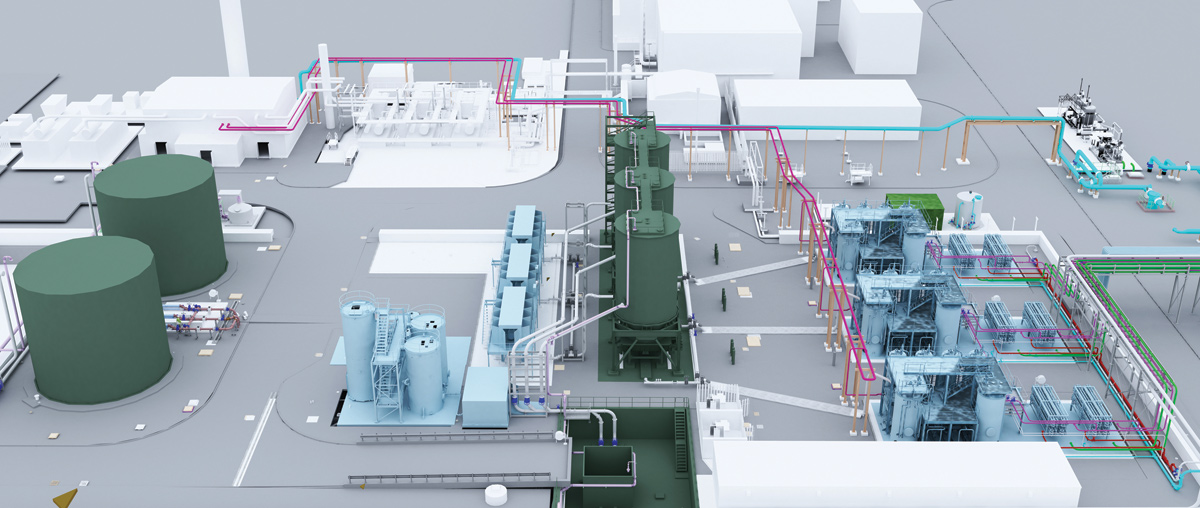

Thermal hydrolysis and liquors treatment increases throughput and biogas generation capacity and provides opportunity to centralise sludge treatment%

Strongford STW is a major sewage treatment works serving the population equivalent of circa 350,000 from Newcastle-under-Lyme and Stoke-on-Trent. The site’s sludge treatment facility provides a major centre for regional operations. Based on a forecast increase in population, it was identified that an increase in treatment capacity would be required to accommodate the local growth. To enable this, Strongford STW was identified by Severn Trent as the ideal location for the implementation of a second thermal hydrolysis plant (THP), following the successful THP implementation at Minworth STW.

Read more