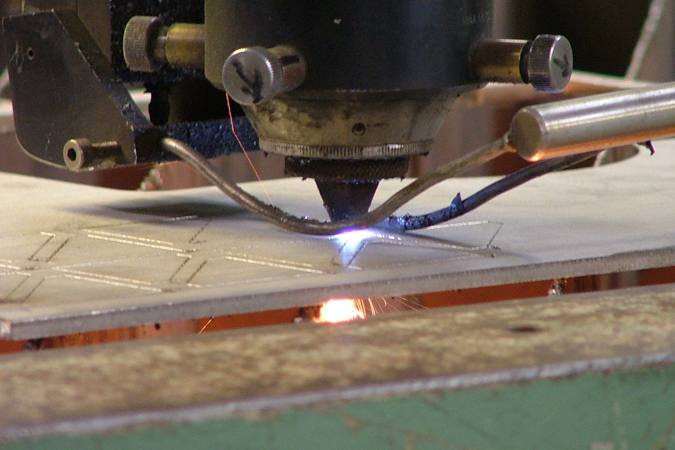

Laser Cutting

Craftsmen in Stainless Steel

The UK's Leading Specialists in Stainless SteelBy combining the latest cutting technology and CNC programming software, high quality cut items can be profiled from sheet and pipe material.

When combined with a sophisticated materials nesting package full utilisation of materials can be achieved resulting in cost effective production. The flat bed cutting area allows fabrication of 3 metres x 1.5 metres, with material thickness from 0.5 mm up to 8 mm in stainless and carbon steel. Using this method material is profiled both quickly and accurately to tolerances of +/-0.125 mm.

The Benefits of Laser Cutting

The laser also gives us the opportunity to offer customers specialized profiled items, such as key rings or engraved items , together with signage, giving intricate detail and precision. Using specialist software, we are able to produce etchings at different diameters of all manor of images and text, for all types of structures and locations.

Laser Cutting Benefits

Laser profiling gives many benefits over conventional cutting, saving on other operations normally needed after using traditional cutting methods.

These include:

- machining

- drilling

- de-burring

- finishing

All resulting in less rejects, material wastage, specialist tooling and material cost savings.

CNC Rotary Cutting

We also offer a revolutionary CNC rotary cutting facility, enabling pipework up to 6 metres in length to be profiled in a manner not readily available until now.

For more info get in touch